The main application of flat enameled wire in new energy vehicle motor:

As the heart of new energy vehicles, there are many electromagnetic wires in the drive motor. If the electromagnetic wire and insulating material cannot withstand the high voltage, high temperature, and high voltage change rate during the operation of the motor, they will be easily broken down and reduce the service life of the motor. At present, when most enterprises produce enameled wires for drive motors of new energy vehicles, due to the simple process and single paint film, the products produced have poor corona resistance and poor thermal shock resistance, which affects the service life of drive motors.

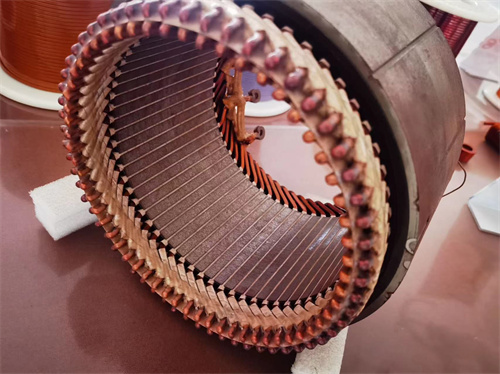

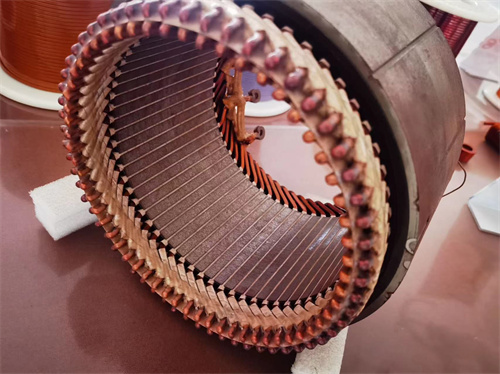

Compared with ordinary round enameled wire windings, under the same volume, flat enameled wire windings have the characteristics of higher energy density, higher motor efficiency, corona resistance, high dielectric strength, zero pinholes, smooth surface, etc., and can replace ordinary round enameled wires Used in new energy vehicle motors.

Using flat enameled wire instead of enameled round wire, theoretically speaking, under the premise of the same space, the filled copper can be increased by 20-30%, and the flat enameled wire winding stator can increase the slot fullness rate by 20%. The improvement of this index means that , when the entire motor space remains the same, the maximum current that can pass through the motor windings can be increased by about 15%, which is equivalent to a 15% increase in the maximum torque and motor power. Conversely, in the case of the same power, the outer diameter and volume of the motor can be reduced, thereby reducing the amount of other materials used in the motor.