What is Continuously Transposed Conductor?

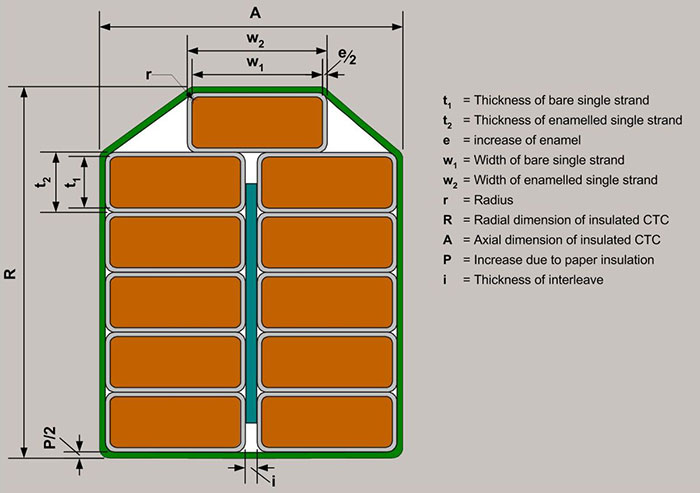

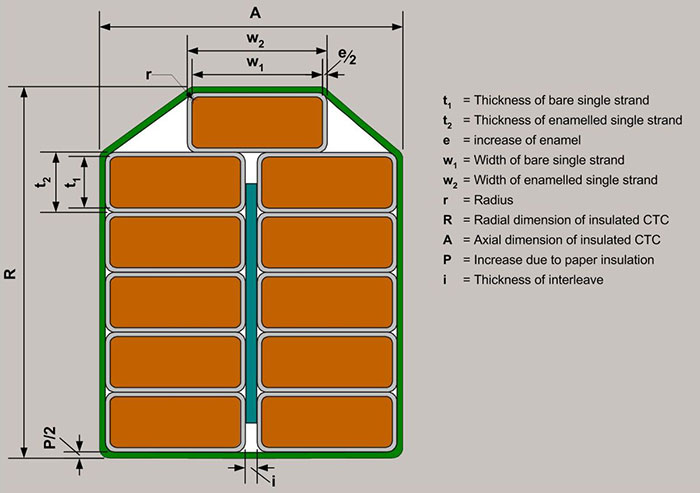

Transposition conductor is made of a certain number of

enameled flat wires arranged in two columns in sequence by special technology, and made of special insulating materials. It consists of a group of enameled rectangular wires, usually with PVF (polyvinylformal) enamel, which are transposed to create a kind of rectangular strand.

CTC configurations come in different lengths to best suit the diameter of transformer windings for different applications and they may also contain between five and 73 wire strands. The finished product is used in power transformers as winding wires.

Continuously Transposed Cable - Advanatges

1. Cost-effectiveness. CTCs can be used with small, less-expensive transformers to reduce the overall cost of the system. The thin insulation helps reduce the space demand for the windings.

2. Ease of use. CTCs have improved winding capabilities. They are also simple for operators and machinery to handle.

3. Reduce electrical loss. CTCs reduce the electrical losses that transformers suffer. They offer faster winding for shortened winding times. CTC windings also help reduce eddy current losses at the end of the winding.

4. Even distribution of heat. Electrical equipment often generates high levels of heat that may damage surrounding components or diminish overall performance. The insulation and spacing improvements that CTCs offer ensures that this heat is evenly distributed across the winding.

5. Improved mechanical strength. CTCs—especially self-bonding CTC types—offer better mechanical strength than alternative materials.

CTC electrical wire Specifications

| Transposition number |

5 – 73 (odd or even optional) |

| Maximum dimension |

height 120 mm, width 26 mm (tolerance ± 0.05 mm); |

| Single conductor size |

thickness a: 0.90 – 3.15 mm, width B: 2.50 – 13.00 mm (tolerance ± 0.01 mm); |

| width thickness of a single conductor is |

2.0 < B / a < 9.0 |

| coating thickness of enameled wire |

0.08-0.12mm |

| Thermal Class |

class H 180℃ or Class E 105 |

| Conductor Materials |

Copper & Aluminum |

CTC Conductor Application

Continuously Transposed Conductors (CTCs) are transposed wire cable systems that can be used in medium and ultra-high power transformers in electrical equipment, Transmission and distribution centers, Military and defense etc.