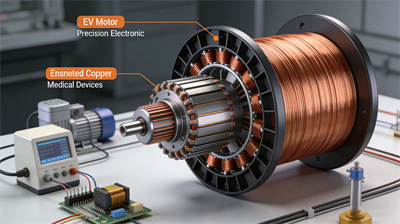

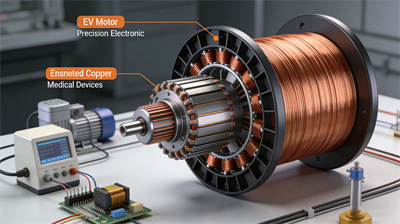

1. IntroductionAs a core conductive component in motors, transformers, and inductors, enameled wire transmits current while ensuring electrical safety via its insulating layer. Widely used in industrial manufacturing, consumer electronics, new energy, and aerospace, it is essential in modern electrical industries.

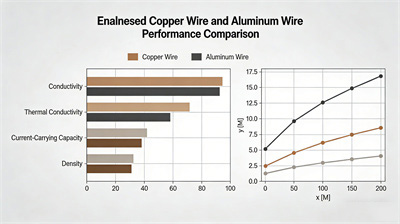

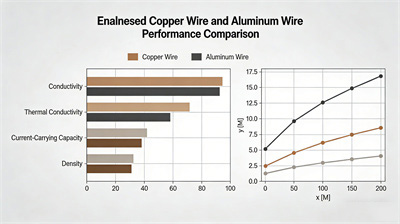

Conductor material selection (copper vs aluminum) directly impacts equipment performance, cost, service life, and application suitability. Significant differences exist between the two in physical properties, electrical performance, and economic costs.

This article systematically compares core differences between enameled copper and aluminum wires, analyzing from basic characteristics, performance, cost, and application scenarios to provide selection guidance.

2. Basic Characteristics2.1 Enameled Copper WireEnameled copper wire consists of a high-purity electrolytic copper core and an insulating enamel layer. Common enamel types (polyurethane, polyester, polyimide) are selected based on temperature and chemical resistance requirements for different scenarios.

Physically, it has a density of 8.96g/cm³, excellent ductility and flexibility for easy winding. With a thermal conductivity of 401W/(m·K) and melting point of 1083℃, it offers superior heat dissipation and high-temperature resistance.

Electrically, copper ranks second in conductivity (58S/m at room temperature) with low resistance, minimizing energy loss and enabling strong current-carrying capacity, suitable for high-power equipment.

2.2 Enameled Aluminum WireEnameled aluminum wire uses an aluminum core with an insulating enamel layer. Special surface treatment is required to remove the aluminum oxide film and ensure enamel adhesion; compatible enamels with anti-oxidation properties are used.

Physically, it has a low density (2.7g/cm³, 30% of copper) for weight advantages, but lower ductility and higher brittleness increase winding difficulty. Its thermal conductivity (237W/(m·K)) and melting point (660℃) are lower than copper.

Electrically, aluminum's conductivity (37S/m at room temperature) is 63% of copper. To match copper's current-carrying capacity, its cross-sectional area must be increased by 50-100%, increasing winding volume.

3. Core Performance Comparison3.1 Electrical ConductivityCopper's conductivity (58S/m) is much higher than aluminum's (37S/m). Per Joule's law, aluminum's higher resistance causes 1.5x more energy loss (I²R) under the same conditions.

This leads to higher temperature rise in aluminum-wired equipment, reducing efficiency and accelerating enamel aging. Copper's low loss maintains stable low temperatures for better reliability.

Aluminum wires compensate by increasing cross-sectional area, but this expands winding volume, limiting use in space-constrained scenarios.

3.2 Thermal PerformanceCopper's thermal conductivity (401W/(m·K)) is 1.7x that of aluminum (237W/(m·K)), enabling faster heat dissipation and better temperature control. Aluminum accumulates heat easily, causing higher temperature rise.

Copper's higher melting point (1083℃ vs aluminum's 660℃) and better heat dissipation protect its enamel layer, enhancing high-temperature stability. Aluminum's higher operating temperature accelerates enamel aging and insulation failure.

Aluminum's higher thermal expansion coefficient (23.1×10^-6/℃ vs copper's 16.5×10^-6/℃) causes greater deformation, loosening connections and increasing fault risks. Copper maintains stable connections.

3.3 Mechanical PerformanceCopper's excellent ductility allows ultra-thin wire drawing and easy winding, improving processing efficiency and yield for precision components.

Aluminum's poor ductility and brittleness cause frequent breakage during processing, increasing difficulty and scrap rates. Its lower tensile strength makes it prone to damage during installation.

Aluminum's surface oxide film offers limited corrosion resistance; harsh environments damage it easily. Copper oxidizes slowly with adherent oxide, providing better long-term corrosion resistance and longer service life outdoors or in humidity.

3.4 Current-Carrying Capacity & Power DensityCopper's unit current-carrying capacity (8-10A/mm² at room temperature) is 1.5x that of aluminum (5-6A/mm²). Aluminum requires 1.5-2x larger cross-sectional area to match copper's capacity.

Copper enables higher power density for miniaturized equipment (e.g., EV motors). Aluminum's larger volume reduces power density, suitable only for large, low-power devices.

4. Cost Considerations4.1 Raw Material CostAluminum's raw material price is 1/3-1/4 of copper. Considering density, its raw material cost per unit length is only 10-15% of copper, offering significant price advantages.

Copper prices fluctuate greatly; aluminum prices are stable, aiding cost control for mass-produced, low-margin products.

4.2 Manufacturing & Processing CostsCopper's ductility ensures high processing efficiency and low scrap rates. Its mature connection processes (welding, brazing, crimping) reduce processing costs.

Aluminum's processing costs are higher due to high scrap rates and special connection requirements (anti-oxidation treatment, special connectors, plating), adding material and process expenses.

4.3 Life-Cycle CostAluminum has low initial costs but high long-term expenses: higher energy loss increases electricity bills, poor stability raises maintenance frequency, and shorter service life (8-12 years) increases replacement costs.

Copper's higher initial cost is offset by low energy loss, minimal maintenance, and long service life (15-20 years), resulting in lower life-cycle costs for high-power, long-running equipment.

5. Application Scenario Selection5.1 Enameled Copper Wire Applications

5. Application Scenario Selection5.1 Enameled Copper Wire ApplicationsHigh-power/efficiency equipment: EV drive motors, industrial motors, transformers, generators (benefits from low loss and high current-carrying capacity).

Precision electronics: Smartphone camera motors, laptop fans, aerospace sensors (ultra-thin wire capability for miniaturization).

Harsh/high-temperature environments: Automotive engine components, industrial heating equipment, outdoor new energy stations, medical devices (excellent high-temperature resistance and corrosion resistance).

Long-life/low-maintenance scenarios: Underground cables, industrial complete sets, medical diagnostic equipment (reduces life-cycle costs).

5.2 Enameled Aluminum Wire ApplicationsCost-sensitive low-medium power equipment: Ordinary household fans, low-end ACs, small water pumps (cost control priority).

Large-scale low-cost installations: Low-voltage distribution lines, rural grid renovations, general small transformers (cost and weight advantages).

Weight-sensitive non-core equipment: Portable electric tools, toy motors, automotive auxiliary appliances (lightweight advantage).

Indoor mild environments: Lighting fixtures, office appliances, low-power toys (stable in dry, normal temperatures).

5.3 Misconceptions & LimitationsMisconception 1: Aluminum is inferior to copper. It is cost-effective for low-requirement, cost/weight-sensitive scenarios.

Misconception 2: Copper can fully replace aluminum. Copper's high cost reduces competitiveness in large-scale, low-profit scenarios.

Aluminum limitations: Unsuitable for high-frequency, high-temperature, or high-reliability scenarios (severe skin effect, low melting point, poor stability).

Copper limitations: High cost restricts use in mass-produced, low-margin low-end products.

6. Conclusion

6. ConclusionEnameled copper and aluminum wires differ in conductivity, mechanical performance, cost, and service life. Copper excels in high-power, precision, harsh environments with better life-cycle economy; aluminum is cost-effective and lightweight for low-medium power, mild scenarios.

Selection should balance equipment needs, cost priorities, environment, and sustainability. Future material innovations (high-performance aluminum alloys, composites) may narrow the performance gap, offering more options.

Performance Parameter Comparison