Enameled wire, as a core component of electrical equipment, is widely used in motors, transformers, relays, electronic coils and other electrical products. Its performance directly determines the safety, stability and service life of the equipment. As the "protective barrier" of enameled wire, the insulation layer not only undertakes the basic function of isolating conductors and preventing electric leakage, but also needs to adapt to complex working conditions such as temperature, chemistry and mechanics in different scenarios.

Among numerous insulation materials, Polyurethane (PU), Polyesterimide (PEI) and Polyimide (PI) occupy the main share of the medium and high-end enameled wire market with their unique performance advantages. There are significant differences among the three in thermal stability, electrical performance, mechanical strength and application scenarios. Choosing a suitable insulation material often becomes a key decision in equipment design and production.

This article will systematically analyze the core differences between polyurethane, polyesterimide and polyimide insulation layers from the dimensions of material characteristics, performance comparison, application scenarios and cost analysis, providing scientific selection basis for practitioners in different industries.

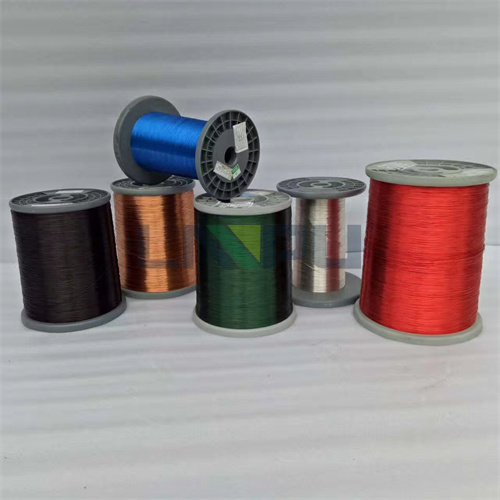

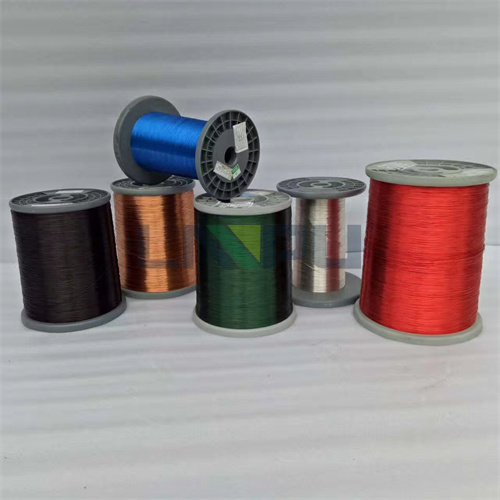

I. What Are Polyurethane, Polyesterimide, and Polyimide Insulations?1.1 Polyurethane (PU) InsulationPolyurethane insulation is an enameled wire insulation material based on polyurethane resin. Chemically, it is polymerized from polyols and isocyanates. The urethane groups in the molecular chain endow it with good flexibility and adhesion.

In terms of production process, polyurethane enameled wire usually adopts the dip-coating and baking process. The polyurethane varnish is evenly applied to the conductor surface and cured at high temperature to form a dense insulation layer. The production process is relatively simple and suitable for mass production. Its basic performance presents the characteristics of "light weight and flexibility". Without modification, its thermal stability and chemical resistance are weak, but it has unique solubility and self-lubricating properties.

1.2 Polyesterimide (PEI) Insulation

1.2 Polyesterimide (PEI) InsulationPolyesterimide insulation is a composite insulation material made by the copolymerization of polyester and polyimide. It combines the low cost and easy processability of polyester with the high temperature resistance and high mechanical strength of polyimide, belonging to a "balanced" high-performance insulation material.

In the production process, it is necessary to accurately control the ratio of the two components and the baking process parameters to ensure the uniformity and bonding stability of the insulation layer. Common formulations are mostly optimized for industrial scenarios and can adapt to the needs of different temperature grades. Its core feature is achieving an excellent balance between cost and performance, filling the market gap between ordinary polyurethane and high-end polyimide.

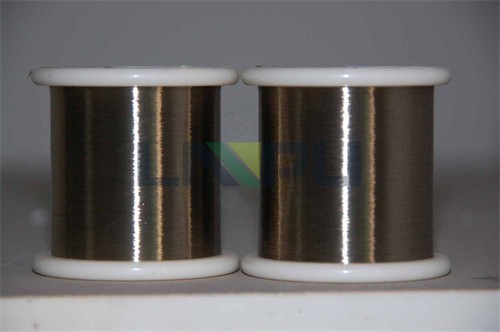

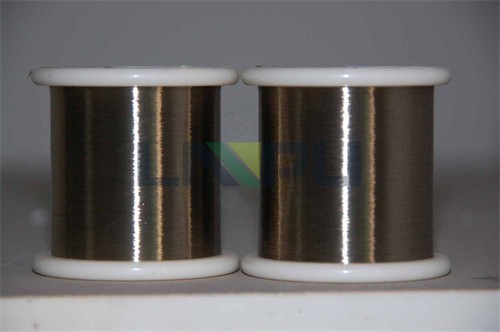

1.3 Polyimide (PI) InsulationPolyimide insulation is a high-end insulation material based on polyimide resin. Its chemical skeleton is composed of imide rings, which have strong intermolecular forces, endowing it with excellent high temperature resistance, radiation resistance and chemical corrosion resistance, and it is known as the "king of insulation materials".

Its synthesis and production process is complex, requiring multiple processes such as low-temperature polycondensation and high-temperature cyclization, which have extremely high requirements on raw material purity and production equipment, resulting in a significantly higher cost than the previous two. The core advantage of polyimide insulation is its stability in extreme environments. It can withstand harsh conditions such as high temperature, vacuum and strong radiation, making it the core choice for high-end precision equipment and special scenarios.

II. Performance Comparison: Analysis of Core Indicators2.1 Thermal Stability: Extreme Differences in Temperature ResistanceThermal stability is a core performance indicator of the insulation layer, directly determining the applicable temperature range and service life of the enameled wire. The continuous operating temperature and thermal aging characteristics of the three are significantly different:

The continuous operating temperature range of polyurethane insulation is 105℃-120℃, with weak thermal shock resistance. Long-term exposure to environments above 80℃ is prone to insulation layer aging and cracking, and it will decompose and fail quickly at high temperatures. Its heat resistance needs to be improved by modification, and it is only suitable for medium and low temperature scenarios.

The continuous operating temperature of polyesterimide insulation can reach 155℃-180℃, and its thermal stability is much better than that of polyurethane. It can withstand short-term high-temperature impact, run stably for a long time under the working condition of 120℃-150℃, and has a slow thermal aging rate, complying with the requirements of international standards such as IEC and NEMA for medium and high temperature insulation materials.

Polyimide insulation has the best thermal stability, with a continuous operating temperature of 200℃-260℃. Some high-end models can be used at 300℃ for a short time. It can still maintain insulation integrity without obvious aging and degradation in high-temperature environments, and has excellent thermal shock resistance, which can adapt to extreme temperature difference scenarios.

2.2 Electrical Performance: Core Guarantee for Insulation and Energy EfficiencyElectrical performance is directly related to the insulation safety and equipment energy efficiency of enameled wire, mainly reflected in three dimensions: dielectric strength, dielectric loss and volume resistivity:

In terms of dielectric strength, the dielectric strength of polyurethane insulation is 15-20kV/mm, which can meet the needs of low and medium voltage scenarios; polyesterimide is 20-25kV/mm, suitable for medium and high voltage equipment; polyimide can reach 25-30kV/mm, with extremely strong insulation breakdown resistance, suitable for high voltage and high frequency scenarios.

In terms of dielectric loss, polyurethane has low dielectric constant and loss factor, excellent energy efficiency performance, and is suitable for high-frequency electronic coils; polyesterimide has moderate dielectric loss, balancing energy efficiency and stability; polyimide has slightly higher dielectric loss, but the loss fluctuation is small under high temperature and high pressure, with outstanding stability.

In terms of volume resistivity, all three have good insulation integrity. Among them, polyimide has the highest volume resistivity, and the insulation performance decays the slowest during long-term use. Polyurethane is easily affected by humidity and temperature, with large fluctuations in resistivity.

2.3 Mechanical Strength: Physical Resistance to Working ConditionsMechanical strength determines the ability of the insulation layer to resist damage during processing, installation and use. The core indicators include wear resistance, flexibility, adhesion and impact resistance:

Polyurethane insulation has excellent flexibility, easy to wind and bend. Its self-lubricating property makes it have good wear resistance, but its adhesion is weak. It is prone to peeling and cracking after external friction, with general impact resistance, and is not suitable for complex mechanical working conditions.

Polyesterimide insulation has excellent comprehensive mechanical properties. Its wear resistance and adhesion are significantly better than those of polyurethane. It can withstand friction and extrusion during processing and installation, with moderate flexibility, which can adapt to the winding needs of most motor windings, and has good impact resistance, suitable for industrial mechanical scenarios.

Polyimide insulation has the highest mechanical strength, with top-level wear resistance, adhesion and impact resistance. It can resist severe friction, impact and vibration, and still maintain insulation layer integrity without cracking or falling off after bending, adapting to extreme mechanical working conditions.

2.4 Chemical Resistance: Adaptability to Complex EnvironmentsIn different application scenarios, the insulation layer needs to resist erosion by chemical factors such as oils, solvents, humidity and corrosive gases. The resistance of the three is significantly different:

Polyurethane insulation has weak chemical resistance, easily eroded by organic solvents and mineral oils, and sensitive to humidity. Long-term exposure to humid environments is prone to aging and degradation, and even mold growth. It is only suitable for dry and non-chemically corrosive scenarios.

Polyesterimide insulation has good oil resistance and solvent resistance, can withstand erosion by most industrial chemicals, and has excellent humidity resistance, which can work stably in humid and dusty industrial environments, but has weak resistance to strong oxidizing chemicals.

Polyimide insulation has comprehensive chemical resistance, can withstand various media such as oils, solvents, strong oxidizing chemicals and corrosive gases, and has excellent moisture-proof and mold-proof properties. It can still run stably for a long time even in harsh corrosive environments such as marine and chemical industries.

2.5 Special Properties: Scenario-Specific Differentiated AdvantagesIn addition to basic properties, the special properties of the three further clarify their scenario adaptability:

Polyurethane insulation has unique solubility, which can realize the bonding and fixing of coils through solvent dissolution, simplifying the processing process. At the same time, some models have self-lubricating functions, reducing winding friction loss, suitable for small electronic coils, relays and other scenarios.

Polyesterimide insulation has excellent compatibility with impregnating resins. Its insulation performance and mechanical strength can be further improved through impregnation treatment. With a balance of cost and performance, it is a "universal choice" for industrial scenarios.

Polyimide insulation has excellent radiation resistance and low outgassing, no harmful substances are released in vacuum environment, and has flame retardant properties. It is the core adaptive material for high-end scenarios such as aerospace, military industry and semiconductors.

III. Application Scenarios: Precisely Matching Insulation Needs3.1 Typical Applications of Polyurethane (PU) InsulationRelying on the advantages of flexibility, low dielectric loss and low cost, polyurethane insulation is mainly used in small electrical equipment with medium and low temperature, low and medium voltage:

In the household appliance field, it is suitable for small motor windings of equipment such as electric fans, washing machines and refrigerators, as well as control coils in air conditioners and microwave ovens; in the electronic component field, it can be used in relays, contactors, small transformers and inductors, especially suitable for the energy efficiency needs of high-frequency electronic coils.

It should be noted that polyurethane insulation is not suitable for high temperature, humid or chemically corrosive environments, such as automobile engine compartments and industrial chemical equipment, otherwise insulation failure is prone to occur.

3.2 Typical Applications of Polyesterimide (PEI) InsulationWith the balanced advantage of performance and cost, polyesterimide is the most widely used medium and high temperature insulation material in the industrial field:

In the industrial motor field, it is suitable for windings of medium and large industrial motors, water pumps and compressors, and can withstand high temperatures generated during equipment operation; in the automotive field, it is suitable for high-temperature components such as generators, starters and ignition coils in the engine compartment, meeting the strict reliability requirements of the automotive industry; in the power equipment field, it can be used in medium and high voltage transformers, traction motors and other equipment, balancing insulation performance and cost control.

3.3 Typical Applications of Polyimide (PI) Insulation

3.3 Typical Applications of Polyimide (PI) InsulationDue to its adaptability to extreme environments, polyimide insulation is mainly used in high-end precision equipment and special scenarios:

In the aerospace field, it is suitable for electrical systems of aircraft engines, satellites and spacecraft, and can withstand extreme working conditions such as high temperature, vacuum and radiation; in the military industry field, it is used in electronic components of weapons and equipment such as radars, missiles and tanks to ensure stability in complex battlefield environments; in the semiconductor and medical fields, it is suitable for high-frequency coils of semiconductor manufacturing equipment and electrical components of high-temperature sterilization medical equipment, and also meets the biocompatibility requirements of medical equipment.

Its high-end cost needs to be supported by extreme performance requirements, and it is generally not necessary to use it in ordinary industrial scenarios.

IV. Cost Analysis: Balancing Value and Investment4.1 Cost Hierarchy Differences

IV. Cost Analysis: Balancing Value and Investment4.1 Cost Hierarchy DifferencesThe costs of the three show a clear hierarchy: polyurethane insulation has the lowest cost, with low raw material prices and simple production processes. The cost per unit length of enameled wire is only 1/5-1/4 of that of polyimide; polyesterimide is at the medium and high-end level, with a cost about 2-3 times that of polyurethane, mainly due to composite resin raw materials and complex production processes; polyimide has the highest cost, with high requirements on raw material purity and cumbersome production processes. Its unit cost is 4-6 times that of polyurethane, belonging to high-end insulation materials.

4.2 Total Cost and Cost-Effectiveness ConsiderationsWhen selecting, it is necessary to consider both the initial cost and the total cost of ownership (TCO): polyurethane has a low initial cost but a short service life, requiring frequent replacement in medium and high temperature scenarios, resulting in high long-term total cost; polyesterimide has a moderate initial cost, long service life and low maintenance cost, suitable for industrial scenarios that require performance and pursue cost-effectiveness; polyimide has a high initial cost, but does not need frequent replacement in extreme environments, avoiding high losses caused by equipment failures, and its total cost of ownership is more advantageous.

Generally speaking, polyurethane is preferred for medium and low temperature, low load scenarios; polyesterimide is preferred for medium and high temperature, industrial-grade scenarios; polyimide is preferred for extreme environments and high-end precision equipment.

V. Selection Guide: Five-Step Precision Screening of Insulation Layers5.1 Step 1: Clarify the Operating Temperature RangeFirst, determine the continuous operating temperature and short-term peak temperature of the equipment: polyurethane is selected for temperatures below 120℃; polyesterimide is selected for 120℃-180℃; polyimide is selected for temperatures above 180℃ or extreme temperature difference scenarios.

5.2 Step 2: Evaluate Electrical Performance RequirementsScreen according to the voltage and frequency requirements of the equipment: polyurethane is selected for low and medium voltage, high frequency scenarios; polyesterimide is selected for medium and high voltage, industrial-grade frequency scenarios; polyimide is selected for high voltage, high frequency or scenarios with extremely high insulation stability requirements.

5.3 Step 3: Analyze Environmental Working ConditionsPolyurethane can be selected for dry and non-corrosive environments; polyesterimide is selected for humid, oily and general industrial corrosive environments; polyimide is selected for extreme corrosive environments such as marine, chemical, radiation and vacuum.

5.4 Step 4: Consider Mechanical Processing NeedsPolyurethane is selected for small components that need frequent winding and bending; polyesterimide is selected for conventional industrial windings and scenarios requiring wear resistance; polyimide is selected for severe vibration, impact or complex processing working conditions.

5.5 Step 5: Balance Budget and Total Cost of OwnershipPolyurethane is selected for low-cost, short-cycle equipment; polyesterimide is selected for industrial equipment that requires long-term stable operation and pursues cost-effectiveness; for high-end precision equipment and extreme working condition equipment, the long-term value of polyimide should be given priority.

VI. Industry Standards and Certifications: Compliance GuaranteeThe selection of insulation layers must comply with global industry standards and sector-specific certifications to ensure product compliance and reliability:

International general standards include IEC 60317 (general standard for enameled wire), NEMA MW 1000 (American standard for motor winding materials), and ASTM D1676 (test standard for insulation material performance). All three must pass the performance verification of the above standards before mass production.

In specific fields, the automotive industry needs to comply with IATF 16949 certification, and polyesterimide is the mainstream choice; the aerospace field needs to pass AS9100 certification, and only polyimide can meet the requirements; medical equipment needs to comply with ISO 13485 certification, and polyimide needs to meet additional biocompatibility requirements.

The standard compliance of insulation materials directly affects the market access and use safety of equipment. The product certification qualification should be confirmed first when selecting.

VII. Future Development Trends of Insulation Materials7.1 Modified Formula UpgradeThe industry is optimizing the performance of existing materials through formula modification, such as improving the high temperature resistance and chemical resistance of polyurethane, reducing the production cost of polyimide, and enhancing the extreme environment adaptability of polyesterimide, further narrowing the performance gap between different materials.

7.2 Green Environmental Protection TrendDriven by environmental policies, low-VOC and degradable insulation materials have become research hotspots. Solvent-free production processes for polyurethane and polyesterimide are gradually popularized, and polyimide is also exploring environmentally friendly raw material substitution schemes, balancing performance and sustainability.

7.3 High-Performance Composite MaterialsTo meet the needs of emerging fields such as new energy vehicles and renewable energy, composite insulation layers with the advantages of multiple materials are developing rapidly, such as polyurethane-polyimide composite layers and polyesterimide-nanomaterial modified layers, which can adapt to more complex working conditions.

ConclusionThere is no absolute advantage or disadvantage among polyurethane, polyesterimide and polyimide insulation layers. The core lies in precise matching with application scenarios. Polyurethane adapts to medium and low temperature small equipment with low cost and high flexibility; polyesterimide dominates industrial medium and high temperature scenarios with cost-effectiveness advantages; polyimide monopolizes high-end special fields with extreme performance.

When selecting, it is necessary to comprehensively consider the five core factors of temperature, electricity, environment, mechanics and cost, combined with industry standards and certification requirements, to achieve the optimal balance between equipment performance and cost. In the future, with the upgrading of material technology, insulation materials will develop towards high performance, environmental protection and compounding, providing a broader space for the innovation of electrical equipment.