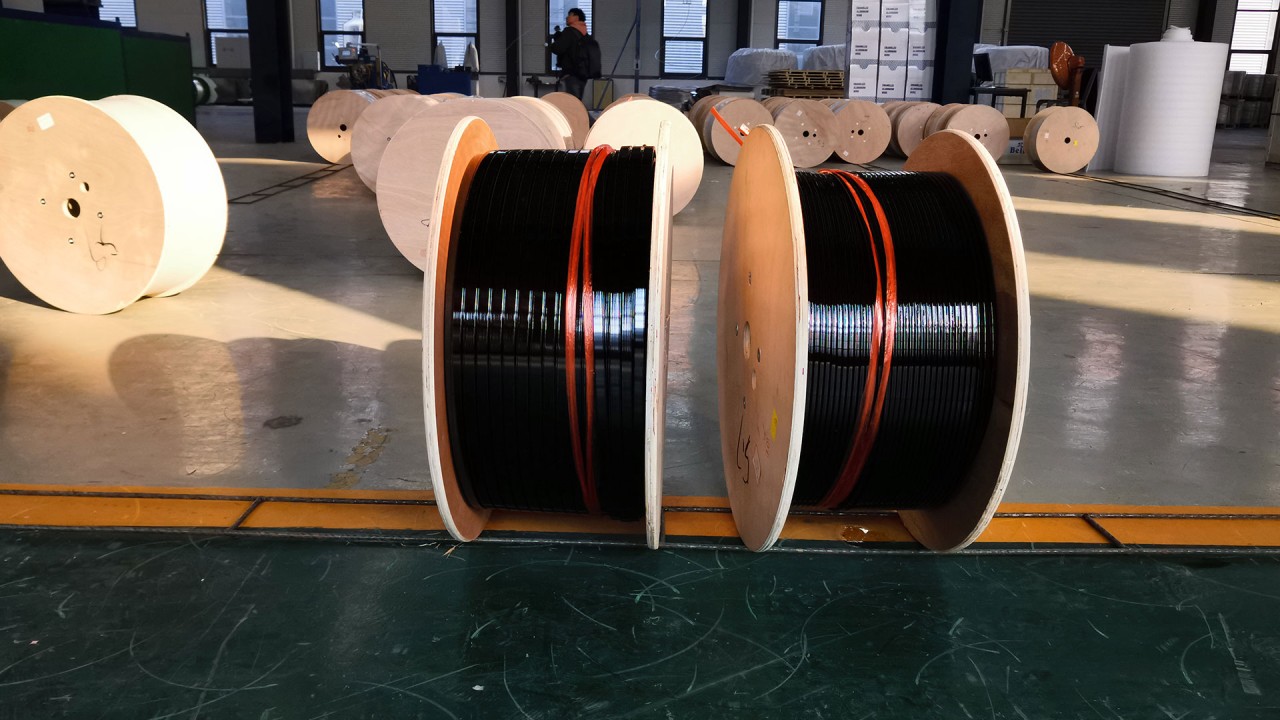

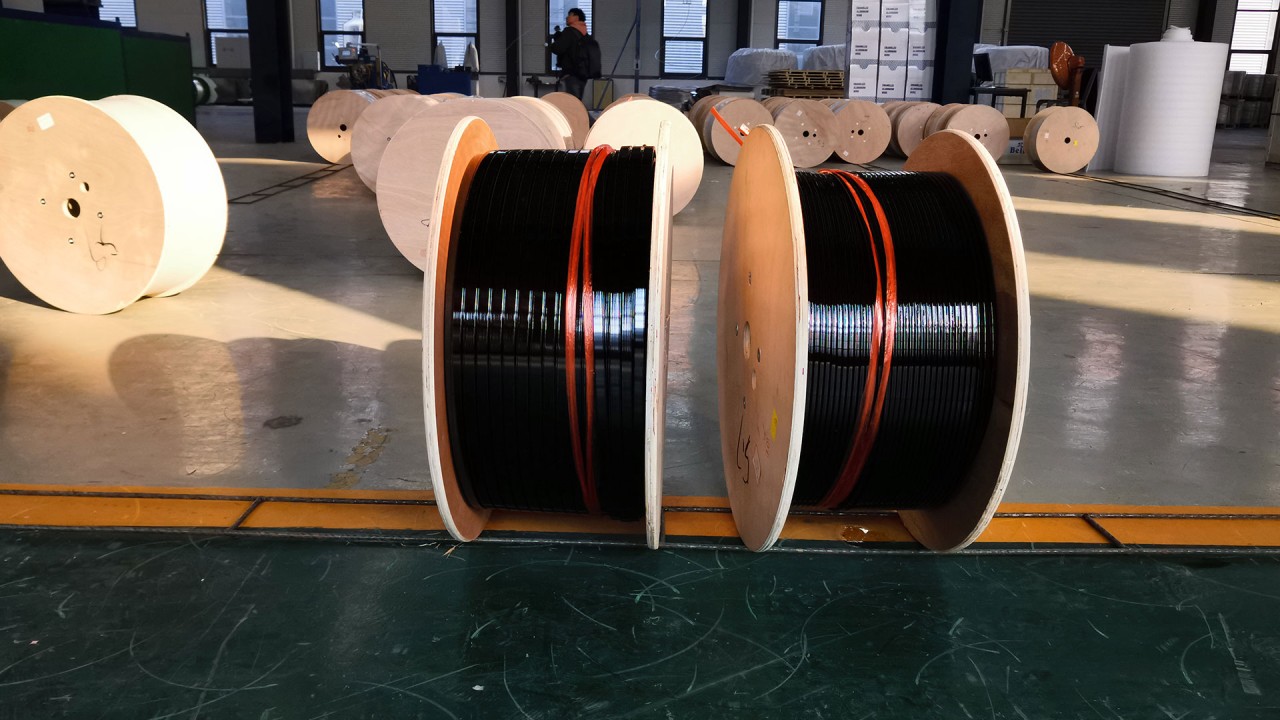

What is aluminium magnet wire? Simply put, it is an insulated electrical wire, usually made of high-purity aluminium as the conductor, coated with a thin heat-resistant insulating layer on the surface. It is specially used for winding coils in electromagnetic equipment, and is also widely known as aluminium magnet wire, which is one of the core materials in the field of winding manufacturing.

Aluminium magnet wire has multiple advantages such as light weight, high cost-effectiveness, excellent electrical conductivity and durability. This unique combination of properties makes it the preferred solution for most winding applications in various industries. This article will detailedly explore the common application scenarios, core advantages of aluminium magnet wire, as well as the key reasons why it stands out among other alternative materials in winding applications.

Core Properties of Aluminium Magnet Wire Suitable for Winding Applications

Core Properties of Aluminium Magnet Wire Suitable for Winding ApplicationsBefore delving into specific application scenarios, we first clarify the core properties that make aluminium magnet wire the preferred material for windings—each property is directly linked to winding performance, accurately solving the core needs in winding manufacturing and use.

1. Lightweight Property: Reduce the Overall Weight of Winding CoilsAluminium magnet wire is 30% lighter than copper magnet wire. This property is crucial for weight-sensitive winding applications. Whether it is equipment in the automotive, aerospace fields, or portable electrical products, lightweight windings can effectively reduce the overall weight of the equipment, thereby improving equipment energy efficiency, portability or operational stability. It is especially suitable for coil winding needs with strict weight restrictions.

2. High Cost-Effectiveness: Reduce Winding Production CostsCompared with copper materials, the raw material cost of aluminium is lower, and using aluminium magnet wire to wind windings does not require sacrificing core electrical performance. This advantage allows manufacturers to effectively control raw material costs when mass-producing winding components, and improve the market competitiveness of products on the premise of ensuring product quality. It is especially suitable for winding manufacturing scenarios such as high-output household appliances and industrial motors.

3. Excellent Electrical Conductivity: Ensure Efficient Operation of WindingsThe thermal conductivity and electrical conductivity of aluminium are second only to copper, which can ensure the efficient transmission of current in winding coils, minimize energy loss, and improve the operating efficiency of electrical equipment. For winding components that operate continuously for a long time (such as industrial motors and transformer coils), excellent electrical conductivity can not only reduce energy consumption, but also reduce coil heating and extend the service life of windings.

4. Good Flexibility and Workability: Adapt to Complex Winding DesignsAluminium magnet wire is flexible and easy to bend, wind and shape. It can not only wind tight small coils, but also adapt to complex winding configurations. This good workability can simplify the winding manufacturing process, reduce labor and equipment costs, adapt to winding design needs of different specifications and uses, and improve production efficiency.

5. Heat and Corrosion Resistance: Adapt to Complex Working EnvironmentsThe insulating coating on the surface of aluminium magnet wire (such as polyurethane, polyester, polyimide, etc.) has excellent high-temperature resistance and chemical corrosion resistance. It can effectively protect the aluminium conductor from high temperature and chemical erosion, extend the service life of winding coils in harsh environments (such as industrial high-temperature workshops and outdoor equipment), and ensure the long-term stable operation of windings.

Tip: In actual content creation, long-tail keywords (such as "heat-resistant aluminium magnet wire for winding" and "flexible aluminium winding wire") can be naturally embedded to accurately meet segmented search needs and improve article SEO effects.

Common Winding Application Scenarios of Aluminium Magnet Wire

Common Winding Application Scenarios of Aluminium Magnet WireCombined with the needs of various industries, we split the winding applications of aluminium magnet wire in different fields according to the priority of application heat and search volume, and detailedly explain its usage methods and adaptation advantages, so that practitioners in different industries can find references that fit their own needs.

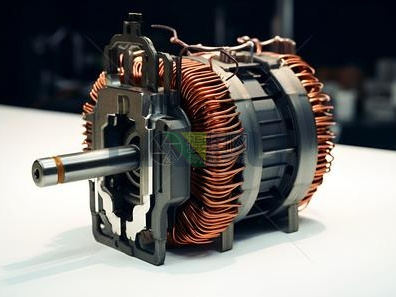

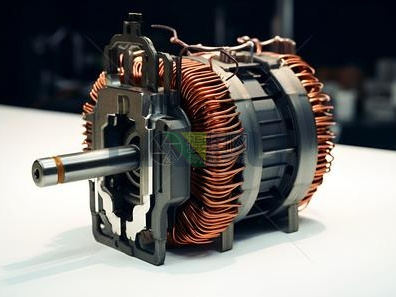

I. Electric Motors and Generators (The Most Demanded Winding Application)Electric motors and generators are the core application scenarios of aluminium magnet wire. Whether it is industrial-grade or household-grade equipment, the internal winding coils are almost inseparable from the support of aluminium magnet wire. With the advantages of light weight and high cost-effectiveness, it has become the mainstream choice of winding materials in this field.

1. Industrial Motor WindingsIn fields such as factory production, mining, and water conservancy projects, AC/DC motors (such as induction motors and servo motors) are widely used in pumps, conveyors, compressors and other equipment, and their internal winding coils are all wound with aluminium magnet wire. The lightweight property of aluminium magnet wire can reduce the overall weight of the motor, facilitating equipment installation and transportation; the high cost-effectiveness is suitable for the mass production needs of industrial motors, and the excellent electrical conductivity ensures the long-term stable operation of the motor, reducing energy consumption and maintenance costs.

2. Household Appliance Motor WindingsDaily household appliances such as refrigerators, washing machines, electric fans, air conditioners, and blenders all require winding coils in their internal small drive motors to achieve kinetic energy conversion. Aluminium magnet wire has low cost and good workability, which is suitable for the high-volume production characteristics of household appliances; at the same time, its flexibility advantage can realize compact winding, adapting to the narrow installation space inside household appliances, and reducing the manufacturing cost of home appliances on the premise of ensuring motor performance, allowing consumers to obtain more cost-effective products.

3. Generator WindingsPortable generators, industrial generators, and generators in the renewable energy field all use a large number of aluminium magnet wire for their winding coils. For portable generators, the lightweight property of aluminium magnet wire can greatly reduce the weight of the equipment and improve portability; for industrial-grade and renewable energy generators, their excellent electrical conductivity and heat resistance can ensure the efficient output of electrical energy by the generator, adapt to the needs of long-term continuous operation, and reduce raw material costs.

Core Keywords: Aluminium magnet wire for motor windings, aluminium wire for generator windings, aluminium windings for AC motors

II. Transformers (Core Windings for Power Distribution and Electronic Equipment)The core function of a transformer is to realize voltage conversion, and the winding coil is the key component for voltage conversion. With the advantages of cost and performance, aluminium magnet wire is widely used in various transformer windings, covering multiple scenarios such as power transmission and electronic equipment.

1. Power Transformer WindingsIn fields such as power grid transmission and substations, high-voltage power transformers and low-voltage power transformers used in buildings and industrial facilities all use aluminium magnet wire for their winding coils. Power transformers have large demand and diverse specifications. The high cost-effectiveness of aluminium magnet wire can greatly reduce the construction and maintenance costs of power equipment; at the same time, its excellent electrical conductivity and heat resistance can adapt to the high-temperature and high-voltage environment during power transmission, ensuring stable voltage conversion and safe power supply.

2. Electronic Transformer WindingsSmall electronic devices such as mobile phone chargers, power adapters, and audio equipment require compact winding coils in their internal small transformers to achieve electrical energy conversion. Aluminium magnet wire has good workability and can be wound into miniaturized and high-density coils, adapting to the compact structural design of electronic equipment; at the same time, its excellent insulation performance can ensure the safe use of electronic equipment and realize efficient voltage conversion on the premise of low cost.

3. Special Transformer WindingsSpecial transformers such as isolation transformers, current transformers, and voltage transformers are widely used in fields such as power detection, medical equipment, and industrial control. Their winding coils have high requirements for stability and durability. Aluminium magnet wire has strong heat and corrosion resistance, which can adapt to the long-term continuous operation needs of special transformers, and its excellent electrical conductivity can ensure detection and control accuracy, adapting to the use requirements of special scenarios.

Core Keywords: Aluminium magnet wire for transformer windings, aluminium windings for low-voltage transformers, aluminium winding wire for power grids

III. Automotive Electrical Systems (A Fast-Growing Winding Application Field)

III. Automotive Electrical Systems (A Fast-Growing Winding Application Field)With the transformation of the automotive industry towards electrification and intelligence, the complexity of automotive electrical systems continues to increase, and the demand for winding materials also continues to grow. With the advantages of light weight and high efficiency, aluminium magnet wire has become one of the core materials for automotive winding applications.

1. Windings for Traditional Automotive Electrical ComponentsThe electrical components of traditional fuel-powered vehicles, such as starter motors, alternators, windshield wiper motors, and power window motors, all use aluminium magnet wire for their internal windings. The lightweight property of aluminium magnet wire can reduce the overall weight of the vehicle and improve fuel economy; at the same time, its strong durability can adapt to the vibration and high-temperature environment during vehicle operation, ensuring the stable operation of electrical components and reducing the incidence of failures.

2. Windings for Core Components of Electric Vehicles (EVs)In the field of new energy vehicles, core components such as traction motors, battery cooling fans, and on-board chargers have higher requirements for winding materials. The excellent electrical conductivity and heat resistance of aluminium magnet wire can meet the high-power and high-speed requirements of new energy vehicle traction motors, supporting efficient vehicle operation; at the same time, its lightweight property can reduce the vehicle weight and improve the cruising range, and the high cost-effectiveness is suitable for the mass production needs of new energy vehicles, promoting the reduction of new energy vehicle costs.

3. Windings for Automotive Power Management TransformersThe power management system of modern vehicles (such as 12V to 48V voltage conversion) requires transformers to realize electrical energy distribution and conversion, and their winding coils are wound with aluminium magnet wire. Aluminium magnet wire can be wound into compact coils, adapting to the narrow installation space inside the vehicle, and its efficient electrical conductivity reduces energy loss during power conversion, improving the operating efficiency of the automotive electrical system.

Core Keywords: Aluminium magnet wire for automotive windings, aluminium windings for new energy vehicle motors, aluminium windings for automotive alternators

IV. Aerospace Field (Adaptation to Special Winding Needs)The aerospace field has extremely high requirements for the weight, stability and environmental resistance of electrical equipment. With the advantages of light weight, high temperature resistance and corrosion resistance, aluminium magnet wire has become an ideal material for special windings in this field, mainly used in electrical components of aircraft, satellites and other equipment.

1. Aerospace Equipment WindingsThe core electrical components of aircraft, such as flight control motors and auxiliary power units (APUs), all use aluminium magnet wire for their winding coils. The lightweight property of aluminium magnet wire is crucial for reducing aircraft weight, which can effectively improve aircraft cruising ability and flight safety; at the same time, its surface special insulating coating can resist extreme high temperature and air pressure environments at high altitudes, ensuring the long-term stable operation of winding coils and ensuring aircraft flight safety.

2. Satellite and Spacecraft WindingsThe electronic systems of satellites and spacecraft require a large number of small and high-precision winding coils to realize signal transmission and energy conversion. Aluminium magnet wire has strong durability, and can resist space radiation environment after special treatment. At the same time, its lightweight and miniaturized winding advantages can adapt to the compact structural design of satellites and spacecraft, ensuring long-term stable operation in harsh space environments.

Core Keywords: Aluminium magnet wire windings for aerospace, aluminium wire for satellite windings, lightweight aluminium magnet wire for aviation

.jpg) V. Renewable Energy Systems (Environmentally Oriented Winding Applications)

V. Renewable Energy Systems (Environmentally Oriented Winding Applications)With the rapid development of the global new energy industry, the demand for renewable energy equipment such as solar energy and wind energy continues to grow. With the advantages of high efficiency and low cost, aluminium magnet wire is widely used in winding coils of various renewable energy equipment, helping the new energy industry reduce costs and increase efficiency.

1. Solar Inverter WindingsThe core function of a solar inverter is to convert the direct current generated by solar cells into alternating current, and its internal winding coils are wound with aluminium magnet wire. The excellent electrical conductivity of aluminium magnet wire ensures efficient electrical energy conversion, reduces energy loss, and improves the overall efficiency of the solar power generation system; at the same time, its high cost-effectiveness can reduce the manufacturing cost of inverters and promote the popularization and application of solar power generation.

2. Wind Turbine WindingsThe generator and control system of wind turbines require a large number of winding coils to convert kinetic energy into electrical energy. The lightweight property of aluminium magnet wire can reduce the load on turbine blades and nacelles, improving the operational stability of wind turbines; at the same time, its strong corrosion resistance can adapt to complex outdoor environments such as wind, rain and temperature fluctuations, extending the service life of wind turbines and reducing maintenance costs.

Core Keywords: Aluminium winding wire for renewable energy, aluminium magnet wire for solar inverters, aluminium windings for wind turbines

VI. Other Common Winding Application ScenariosIn addition to the above core scenarios, aluminium magnet wire is also widely used in winding coils of various small electrical equipment and special equipment, covering multiple fields such as industry, people's livelihood and medical care, showing extremely strong application versatility.

1. Electromagnet WindingsElectromagnets in industrial hoisting equipment, medical equipment (such as MRI machines), and laboratory equipment all use aluminium magnet wire for their winding coils. The flexibility advantage of aluminium magnet wire can realize customized winding, adapting to the design needs of electromagnets of different specifications; at the same time, its excellent electrical conductivity ensures that electromagnets generate stable and strong magnetic fields, meeting the use requirements of equipment.

2. Audio Equipment WindingsThe sound-generating and signal-transmitting components in audio equipment such as speakers, microphones, and amplifiers require small and high-precision winding coils. The lightweight property of aluminium magnet wire can reduce the mass of the coil, improving the sound effect and signal transmission clarity of audio equipment; at the same time, its good workability can be wound into miniaturized coils, adapting to the compact structural design of audio equipment.

3. Small Electronic Equipment WindingsSmall electronic devices such as toys, remote controls, and power banks require compact winding coils for their internal drive components and power management components. Aluminium magnet wire has low cost and good workability, which is suitable for the production needs of such high-volume and low-cost products; at the same time, its miniaturized winding advantage can adapt to the compact structure of electronic equipment, ensuring the normal operation of the equipment.

Core Keywords: Aluminium winding wire for electromagnets, aluminium magnet wire for audio equipment, aluminium windings for small devices

Key Considerations for Winding with Aluminium Magnet Wire

Key Considerations for Winding with Aluminium Magnet WireTo ensure the performance and service life of aluminium magnet wire windings, combined with industry practical experience, we summarize the following 4 key considerations to provide practical references for manufacturers and engineers and improve the quality of winding production.

1. Reasonably Select Insulating CoatingSelect the appropriate insulating coating according to the operating temperature and environment of the winding: for low-temperature environments (such as household appliance motors), aluminium magnet wire with polyurethane coating can be selected; for high-temperature environments (such as industrial motors and aerospace equipment windings), aluminium magnet wire with high-temperature resistant coating such as polyimide can be selected to ensure that the insulating layer can resist high temperature and chemical corrosion in the working environment for a long time and protect the aluminium conductor.

2. Accurately Select Wire Gauge SpecificationAccording to the current capacity and power requirements of the winding, accurately select the wire gauge specification of aluminium magnet wire to balance electrical conductivity, current-carrying capacity and coil size. Too thin wire gauge will lead to insufficient current-carrying capacity and severe coil heating; too thick wire gauge will increase the winding volume, waste materials and affect the overall structural design of the equipment.

3. Optimize Winding ProcessDuring the winding process, it is necessary to optimize the winding tightness and configuration to ensure that the coil is wound tightly and arranged neatly, so as to maximize electrical conductivity and reduce energy loss. At the same time, using the flexibility advantage of aluminium magnet wire, tighter winding can be realized, improving winding density and adapting to the needs of miniaturized equipment; avoid excessive force during winding to prevent damage to the insulating layer.

4. Ensure Component CompatibilityWhen winding the winding, it is necessary to ensure the compatibility between the aluminium magnet wire and other components (such as connectors, iron cores, insulating materials), so as to avoid chemical reactions between different materials affecting the winding performance. At the same time, pay attention to the anti-oxidation treatment of the aluminium conductor to prevent the aluminium conductor from oxidizing during long-term use, leading to poor contact and decreased electrical conductivity.

Core Keywords: Insulation selection for aluminium magnet wire, wire gauge for aluminium winding wire, winding process optimization

Future Development Trends of Aluminium Magnet Wire Winding ApplicationsCombined with the global industrial upgrading and technological development trends, we analyze the four major future trends of aluminium magnet wire in winding applications to help practitioners grasp the industry direction, layout relevant products and technologies in advance, and seize market opportunities.

1. New Energy Vehicles Drive Demand ExplosionWith the continuous improvement of the global penetration rate of new energy vehicles, the demand for core components such as traction motors and on-board chargers continues to grow, and the demand for lightweight, high-efficiency and low-cost aluminium magnet wire will also increase significantly. In the future, aluminium magnet wire will become the core material for new energy vehicle windings, driving the rapid expansion of the industry scale.

2. Sustained Growth in Demand in the Renewable Energy FieldDriven by the global "dual carbon" goal, the renewable energy industry such as solar energy and wind energy continues to expand, the demand for solar inverters and wind turbines continues to increase, and the demand for aluminium magnet wire for their internal windings will also grow synchronously. Especially in the field of large wind turbines and concentrated solar power plants, the application space of aluminium magnet wire will be further expanded.

3. Insulation Technology Upgrade Expands Application ScenariosWith the continuous upgrading of insulating material technology, new insulating coatings (such as nano-coatings) will be gradually applied to aluminium magnet wire, further improving its high-temperature resistance, radiation resistance and corrosion resistance, expanding the application scenarios of aluminium magnet wire in high-temperature, high-pressure and harsh environments, such as special windings in aerospace, high-end industrial equipment and other fields.

4. Miniaturization of Electronic Equipment Drives Wire Gauge RefinementWith the transformation of consumer electronics and industrial control equipment towards miniaturization and high precision, the requirements for miniaturization and high density of winding coils are constantly increasing, which will drive aluminium magnet wire to develop towards finer wire gauge. Fine-gauge aluminium magnet wire will be widely used in the winding of small electronic equipment and micro motors to meet the needs of equipment miniaturization design.

Core Keywords: Future trends of aluminium magnet wire windings, aluminium windings for new energy vehicles, insulation technology upgrade of aluminium magnet wire

.jpg)