Whether developing traction motors for new energy vehicles, industrial water pump motors, or household air conditioner motors, selecting magnet wire is not simply a matter of "purchasing by specification." It requires comprehensive decision-making based on the motor's application scenario, performance goals, and production costs.

This article starts from the practical needs of manufacturers, sorts out the complete logic of magnet wire selection, helps you avoid common pitfalls, and select the most suitable product.

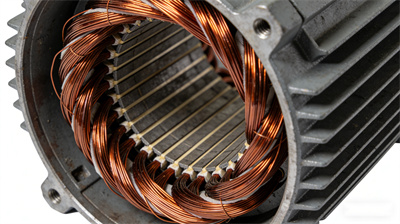

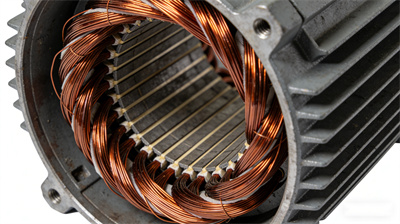

I. Essential Knowledge Before Selection: Core Basics of Motor Magnet Wire

Before starting the selection process, clarifying the core composition and classification logic of magnet wire can help you quickly locate your demand direction and avoid being confused by complex parameters.

1.1 Core Composition of Magnet Wire: Two Key Factors Determining Performance

Although the structure of magnet wire seems simple, it directly determines the core performance of the motor and mainly consists of two parts:

Conductive core: The core that conducts current, mainly made of copper and aluminum. The two differ significantly in conductivity, weight, and cost, making them the primary decision point for selection;

Insulating enamel layer: An insulating protective layer wrapped around the core. Its high-temperature resistance, wear resistance, and dielectric strength directly relate to the motor's service life and safety stability.

1.2 Three Main Classification Dimensions of Magnet Wire for Motors

According to different application scenarios of motors, magnet wire can be classified by three dimensions, and each type has clear applicable scenarios:

By core material: Copper-core magnet wire has high conductivity and ductility, making it the first choice for mid-to-high-end motors; aluminum-core magnet wire is lightweight and cost-effective, suitable for low-power, budget-sensitive scenarios such as small fan motors;

By insulating enamel type: Polyester (PE) magnet wire resists temperatures up to 130°C, suitable for normal-temperature scenarios such as household appliances; polyurethane (PU) magnet wire resists temperatures up to 155°C, has good flexibility, and is suitable for fine-gauge windings;

Polyamide-imide (PAI) magnet wire resists temperatures above 220°C and has excellent corona resistance, making it a core choice for new energy vehicles and industrial high-temperature motors;

By wire shape: Round magnet wire is easy to wind and compatible with conventional automated equipment, mostly used in small motors; rectangular magnet wire like

enameled rectangular copper wire has a high slot fill factor, which can improve motor power density, and is the mainstream choice for high-power products such as new energy vehicle traction motors.

1.3 Unignorable Industry Standards: Baseline Requirements for Selection

Magnet wire selection must comply with industry standards, which is the basis for motors to pass certification and enter the market:

Basic standards: IEC 60317 and UL 1446 specify core indicators such as insulation class, temperature resistance range, and dielectric strength, which are general requirements for all motor magnet wires;

Segment-specific standards: For example, automotive motors must comply with the ISO/TS 16949 standard to ensure magnet wire can withstand complex working conditions such as vibration and high temperature; industrial motors must meet the GB/T 6109 series standards.

.jpg)

II. Step 1: Anchor Motor Scenario and Performance Goals to Clarify Selection Direction

There is no "best" magnet wire, only the "most suitable" one. The first step in selection is to accurately define the motor's application scenario and core performance goals, which is the basis for all decisions.

2.1 Match Core Requirements by Motor Type

Different types of motors have vastly different requirements for magnet wire. Blindly using a universal type can lead to performance waste or failure risks:

New energy vehicle traction motors: Core requirements are high-temperature resistance (above 180°C), high conductivity, and corona resistance. Therefore, a combination of copper core + PAI insulating enamel must be used, and some high-end models also need to be matched with rectangular wires to improve power;

Industrial water pump/compressor motors: Need to withstand 24-hour continuous operation and mechanical vibration. Copper-core magnet wire with strong wear resistance and high mechanical strength should be selected, with an insulation class of at least 155°C (Class F);

Household refrigerator/fan motors: Budget-sensitive with mild working conditions. Aluminum core + PE magnet wire or small-gauge copper core PE magnet wire can be selected to meet basic efficiency requirements;

Aerospace/medical motors: Require high adaptability to extreme environments. Special magnet wire with resistance to high and low temperatures (-55°C to 220°C) and low outgassing, such as polyimide (PI) insulating enamel products, should be selected.

2.2 Clarify Non-Negotiable Performance Indicators

After scenario positioning, 3-5 core performance indicators need to be extracted as hard constraints for selection:

Power output: High-power motors require thick-gauge copper core wires with low resistance to ensure current conduction efficiency; small-power motors can use fine-gauge wires or aluminum core wires;

Efficiency target: To meet the IE4 high-efficiency motor standard, copper core wires must be used, and the wire cross-section must be accurately matched to reduce I²R losses;

Operating temperature: The maximum temperature of the motor during operation determines the insulation class. For example, if the motor's peak temperature is 160°C, 180°C (Class H) magnet wire should be selected to reserve a safety margin;

Service life: Industrial motors requiring a service life of more than 10 years need to use magnet wire with excellent anti-aging performance such as PAI; household motors require a service life of 5-8 years, and PE magnet wire can meet the demand.

III. Step 2: Disassemble Technical Indicators to Accurately Match Selection Parameters

After clarifying the demand direction, it is necessary to deeply disassemble the key technical indicators of magnet wire. These indicators directly correspond to the motor's performance, lifespan, and reliability, and are the core link of selection.

3.1 Conductivity and Resistance: Core Influencing Factors of Efficiency

Conductivity is the core indicator of magnet wire and directly determines the energy loss of the motor:

Copper vs. Aluminum: Copper has 60% higher conductivity than aluminum. Under the same power, the energy consumption of copper-core motors is 10-15% lower than that of aluminum-core motors. Therefore, high-efficiency motors and high-power motors prefer copper cores;

Wire gauge: The larger the wire cross-sectional area, the lower the resistance and the lower the loss. However, it is necessary to combine the motor slot size to avoid "large wire in small slot" which causes winding difficulties;

Stranding method: Multi-strand stranded wire has better flexibility and vibration resistance than single-strand wire, suitable for scenarios with frequent vibration such as industrial motors, which can reduce the risk of fatigue fracture.

3.2 High-Temperature Resistance: The "Stabilizing Force" of Motor Lifespan

The insulating enamel layer of magnet wire is the most vulnerable part of the motor, and high temperature is the main cause of insulation aging. Accurate matching is essential during selection:

Insulation class matching: Class B (130°C) is suitable for household normal-temperature motors; Class F (155°C) is suitable for industrial continuous operation motors; Class H (180°C) and above are suitable for new energy and high-temperature environment motors;

Thermal shock resistance: Motors with frequent start-stop cycles (such as elevator motors and EV motors) need to pay attention to the thermal shock performance of magnet wire to avoid enamel layer cracking caused by alternating hot and cold;

Aging lifespan: At rated temperature, the lifespan of PAI magnet wire is 2-3 times that of PE magnet wire. Although the cost is 30% higher, it can reduce the after-sales maintenance cost of the motor.

3.3 Mechanical Strength: Guarantee for Winding and Operation Reliability

Magnet wire endures tension and bending during winding and may be affected by vibration during operation. Insufficient mechanical strength can lead to production scrap or operation failures:

Wear resistance: High-speed winding of automatic winding machines will rub the enamel layer. Magnet wire with poor wear resistance is prone to enamel layer damage, leading to motor short circuits. It is recommended to select products with an enamel layer thickness of 20-40μm;

Flexibility: Small motors have narrow slots and require magnet wire with good flexibility. PU magnet wire performs better than PE magnet wire in this aspect;

Tensile strength: Copper core wire has 40% higher tensile strength than aluminum core wire, which is not easy to break during winding and is suitable for automated mass production.

3.4 Dielectric Strength and Environmental Resistance: Baseline for Safe Operation

Dielectric strength determines the insulation capacity of magnet wire, and environmental resistance adapts to different working scenarios. Both jointly ensure motor safety:

Dielectric strength: The higher the motor voltage, the higher the requirement for dielectric strength. Household motors require ≥600V, and industrial high-voltage motors require ≥1000V;

Corona resistance: High-voltage motors (such as wind power motors and EV traction motors) must use corona-resistant magnet wire to avoid insulation layer breakdown under high voltage;

Chemical resistance: Motors operating in oily, humid, or corrosive environments (such as marine motors and chemical pump motors) need to use special magnet wire that is oil-resistant and water-resistant.

IV. Step 3: Balance Cost, Manufacturability, and Supply Chain for Optimal Decisions

For manufacturers, selection must not only meet performance requirements but also balance cost control, production efficiency, and supply chain stability to achieve a balance between technology and business.

3.1 Cost Optimization: Do Not Blindly Pursue High-End, Only Choose "Cost-Effective Matching"

Magnet wire accounts for 20-30% of motor material costs. Reasonable selection can significantly reduce costs while avoiding insufficient performance:

Boundary of copper-aluminum replacement: Motors with power ≤1.5kW and efficiency requirement ≤IE2 can use aluminum core wire, reducing material costs by 30-40%;

However, for motors with power ≥5kW or high-efficiency motors, the energy consumption advantage of copper core wire can offset the cost difference;

Enamel layer cost balance: PE magnet wire can be used in conventional scenarios. For high-temperature scenarios, PAI magnet wire is preferred instead of more expensive PI magnet wire blindly;

Accurate gauge matching: Calculate the optimal wire cross-section through motor simulation to avoid "over-spec waste". Reducing one wire gauge can lower costs by 5-8%.

3.2 Manufacturability: Adapt to Production Equipment and Reduce Scrap Rate

The selection of magnet wire directly affects production efficiency. Choosing the wrong type can lead to a surge in scrap rate:

Winding equipment compatibility: Existing round wire winding machines cannot process rectangular wire directly. Switching requires equipment upgrades, resulting in high investment costs;

Enamel adhesion: Magnet wire with poor adhesion is prone to enamel peeling during winding, with a scrap rate of up to 10% or more. Samples should be requested to test winding performance during selection;

Welding convenience: Copper core wire is easy to weld, with a welding qualification rate of over 99%; aluminum core wire requires special equipment for welding, with a qualification rate of about 95%, suitable for mass standardized production.

3.3 Supply Chain Stability: Avoid Delivery Delay Risks

The supply cycle of magnet wire directly affects the motor production plan. Supply chain conditions should be considered during selection:

Standard products: Standard gauge copper core PE/PU magnet wire has a supply cycle of 2-4 weeks, which can meet regular production needs;

Customized products: Customized products such as high-temperature resistant, fine-gauge, or rectangular magnet wire have a supply cycle of 6-8 weeks, requiring advance procurement planning;

Raw material fluctuation response: When copper prices fluctuate significantly, long-term agreements can be signed with suppliers to lock in prices; aluminum core wire is less affected by raw material fluctuations, suitable for stable production sensitive to costs.

V. Practical Cases: Magnet Wire Selection Schemes for Different Scenarios

Combined with actual application scenarios, the following three typical cases can be used as selection references, covering the core needs of different types of motors:

4.1 New Energy Vehicle Traction Motor (150kW)

Core requirements: High power density, 180°C high-temperature resistance, corona resistance, long lifespan;

Selection scheme: Rectangular copper core + PAI insulating enamel (Class H) with corona resistance treatment;

Implementation effect: Motor efficiency reaches 95%, service life exceeds 10 years, passes ISO 12384 automotive certification, and adapts to vehicle requirements.

4.2 Industrial Wastewater Pump Motor (7.5kW)

Core requirements: 24-hour continuous operation, oil resistance, high mechanical strength;

Selection scheme: Round copper core + modified PE enamel (Class F) with thickened enamel layer (35μm); Welcome to see LP

enameled round copper wire.

Implementation effect: No failures during continuous operation, energy consumption reduced by 5% compared with ordinary wires, and oil resistance passed 500-hour testing.

4.3 Household Refrigerator Fan Motor (0.3kW)

Core requirements: Low cost, mild working conditions, meeting basic efficiency;

Selection scheme: Round aluminum core + PE enamel (Class B);

Implementation effect: Material cost reduced by 35%, efficiency meets IE2 standard, and complies with household appliance energy efficiency label requirements.

VI. Selection Pitfall Guide: 4 Common Mistakes by Manufacturers

In actual selection, many manufacturers encounter problems due to ignoring details. The following are pitfalls that need to be avoided:

1. Insufficient temperature margin: Using 130°C magnet wire for a motor with a peak temperature of 140°C reduces lifespan by 50%; the correct approach is to reserve a 20-30°C safety margin;

2. Blind cost reduction with aluminum core: Replacing copper core with aluminum core in high-power motors reduces costs but increases energy consumption by 15-20%, failing to pass high-efficiency certification;

3. Ignoring winding compatibility: Purchasing rectangular wire without confirming whether the equipment can process it leads to production failure and delivery delays;

.jpg)