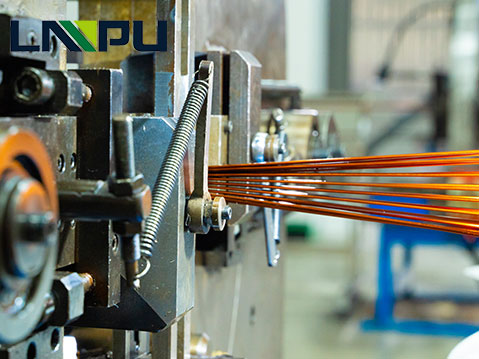

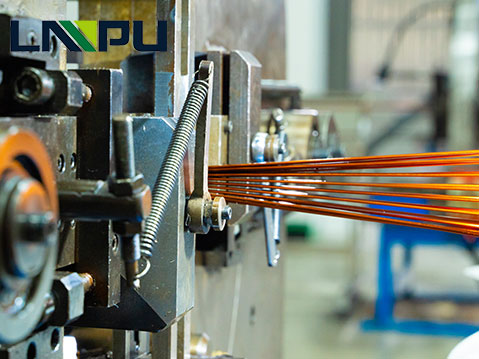

Continuously Transposed Cable are transposed and enameled wire cables wrapped in insulation. CTCs offer a wide range of potential wire positions to end-users and come in many different configurations. Rectangular Copper Strands With Class H Insulation Layer is composed of Class 180 enameled flat copper wire covered paper, widely sell in the ASIA. The wires can reduce the cost of transformer and other electric equipment.

A rectangular copper strand with a Class H insulation layer is a specific type of high-performance conductor commonly used in electrical windings, particularly in applications that demand high power density and operate at elevated temperatures.

This construction is often referred to as magnet wire (when enameled) or can be a component of Litz wire (when multiple insulated strands are bundled).

Conductor and Insulation Features

Rectangular Copper Strand

Shape and Efficiency: Using a rectangular or square cross-section (instead of traditional round wires) allows for a much higher copper filling factor (or packing factor) within the coil space (e.g., in a motor slot). This minimizes wasted space, leading to more efficient windings, higher power density, and better thermal performance.

Applications: Rectangular conductors are increasingly popular in high-performance electrical machines, such as the motors used in electric vehicles (EVs), where a high torque density is essential.

Class H Insulation Layer

Thermal Rating: Class H is a standard thermal rating for electrical insulation systems. It signifies that the insulation is capable of withstanding a maximum continuous operating hot spot temperature of 180°C.

Insulation Material: Insulation systems that meet Class H requirements typically use materials like polyester-imide enamel, silicone elastomers, or similar high-temperature resistant organic and inorganic materials.

Purpose: The insulation layer provides an electrical barrier to prevent short circuits between adjacent turns of the copper conductor in a winding, while also offering resistance to heat, moisture, and chemical