Send 500kg class 180 Fiberglass Covered Rectangular enamelled conductor of copper to Israel.

Manufacturing & Processing ConsiderationsWinding: Requires careful handling and specialized machinery to bend the rectangular wire without damaging the insulation or deforming the conductor.

Impregnation: After winding, the coils are often vacuum-pressure impregnated (VPI) with a special resin or varnish. This varnish locks the windings in place, improves heat transfer (cooling), and provides additional environmental protection. The fiberglass sleeve is excellent at absorbing and wicking this varnish.

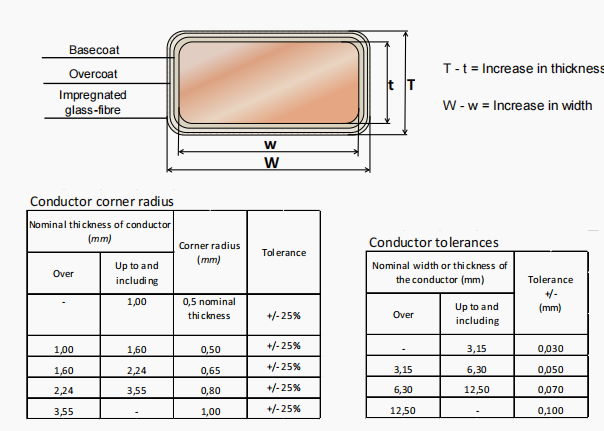

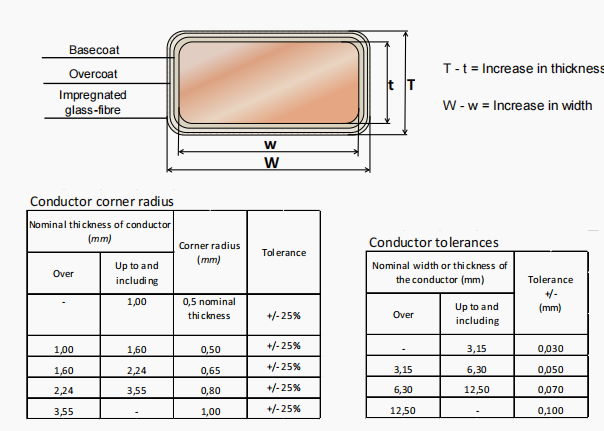

Our customer Roman need 500 Kg of Alternative Fiberglass Covered Flat Copper Wire fibre 180: 5.1 X 2.53 mm, Isolation 0.35 mm.

Key Characteristics & Advantages

| Feature |

Description & Advantage |

| High Temperature Rating |

The primary advantage. Allows for use in high-power-density applications where heat buildup is significant. |

| Excellent Space Factor |

Rectangular shape fills the slots of motors/generators more efficiently than round wires, leading to higher power output. |

| Superior Dielectric Strength |

The combination of enamel and fiberglass provides very high resistance to electrical breakdown, especially from sharp edges and under high voltage spikes. |

| Outstanding Mechanical Ruggedness |

Highly resistant to abrasion, cutting, and stretching during the demanding coil winding and forming processes. |

| Good Chemical Resistance |

Resistant to moisture, oils, varnishes, solvents, and other chemicals commonly found in industrial environments. |