At the 2023.12.28 Xiaomi Auto Press Conference, Lei Jun said that Xiaomi Auto is a major leap for Xiaomi. It is a leap from mobile phones and AIoT to cars. It is a leap forward in long-term investment and deep cultivation of underlying core technologies. It is a coming-of-age ceremony for Xiaomi’s modern industrial intelligent manufacturing capabilities. The leap is also a key leap forward for the complete closed loop of "the whole ecology of people, cars and homes".

Lei Jun said: The motor is the heart of new energy vehicles. The speed determines the performance of this heart. Behind the surging power of Yiqi Juechen are three high-speed Xiaomi super motors: starting from 21,000rpm, and even 27,200rpm to challenge the limit. Your desperate belief in speed, I will use my strength to protect at all costs.

Xiaomi's first super motor V6 series introduces AI simulation technology, performs topology optimization more than 200,000 times, and reaches an astonishing speed of 21,000 rpm. Faster acceleration, higher top speed, lower energy consumption, leading in its class. Xiaomi super motor V8s challenges the new peak of industry speed. The newly developed ultra-high silicon steel material and the redesign of the rotor structure and heat dissipation system bring an unprecedented leap in speed, with a power of up to 425kW.

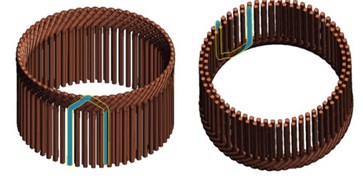

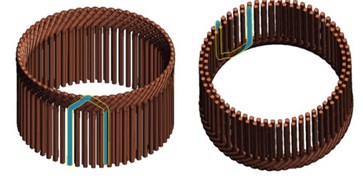

It adopts the industry's better pin-type flat wire winding design, and the stator and rotor pole slots of 54 slots and 6 poles are matched. The slot full rate skyrocketed to 77%, and the iron loss rate was significantly reduced by 25%, resulting in a 0.3% increase in overall motor efficiency. Customized stator double-circulation three-dimensional oil circuit, the first S-type three-dimensional heat dissipation of the rotor, achieving a larger heat dissipation area under the same volume, the maximum temperature is reduced by 30°C, and the comprehensive heat dissipation efficiency skyrockets by more than 50%.

Enameled wire is mainly made of bare wire that has been annealed and softened, and then painted and baked multiple times. Affected by raw material quality, process parameters, production equipment, environment and other factors, the quality characteristics of various enameled wires are different, but they all have four major properties: mechanical properties, chemical properties, electrical properties, and thermal properties.

Flat enameled wire has better softness and flexibility, and has excellent performance in current carrying capacity, transmission speed, heat dissipation performance and occupied space. It is especially suitable as a jumper between circuits in electrical and electronic equipment.

Compared with

enameled round wire, flat enameled wire has a larger cross-sectional area, and its heat dissipation area is also increased accordingly. The heat dissipation effect is significantly improved, and it can also greatly improve the "skin effect" (when alternating current passes through a conductor, the current will be concentrated on Flows over the surface of the conductor), reducing high-frequency motor losses.

As the heart of new energy vehicles, there are many electromagnetic wires in the drive motor. If the electromagnetic wires and insulation materials cannot withstand the high voltage, high temperature, and high voltage change rate during motor operation, they will be easily broken down and reduce the service life of the motor. At present, when most companies produce enameled wires for new energy vehicle drive motors, due to the simple process and single paint film, the products produced have poor corona resistance and poor thermal shock resistance, which affects the service life of the drive motor.

Compared with ordinary round enameled wire windings,

flat enameled wire windings have the characteristics of higher energy density, higher motor efficiency, corona resistance, high insulation strength, zero pinholes, smooth surface, etc. under the same volume, and can replace ordinary round enameled wires. Used in new energy vehicle motors.

Using flat enameled wires instead of enameled round wires can theoretically increase the filling of copper by 20-30% while maintaining the same space. The flat enameled wire winding stator can increase the slot fill rate by 20%. The improvement of this indicator means that , while the entire motor space remains unchanged, the maximum current that can pass through the motor winding can be increased by about 15%, which is equivalent to a 15% increase in the maximum torque and motor power. In turn, with the same power, the outer diameter and volume of the motor can be reduced, thereby reducing the amount of other materials used in the motor.

Such an excellent motor needs to be matched with equally excellent electronic control. To this end, Xiaomi has carried out special optimization based on the characteristics of the motor and developed its own high-energy-efficiency silicon carbide electronic control to fully unleash the wild performance of Xiaomi's super motor.

Over the past three years, Xiaomi has continued to innovate in the field of motor electronic control. So far, 132 patents have been applied for and 44 have been authorized. At the same time, it has obtained the "International Leading Certification" issued by the China Electrotechnical Society & National New Energy Vehicle Innovation Center.

(The technical parameters and pictures of millet cars all come from the network)Therefore, enameled wires, especially enameled flat wires, are used more and more frequently in new energy vehicles. If you want to know about enameled wire, welcome to our webiste:

LP Industry.