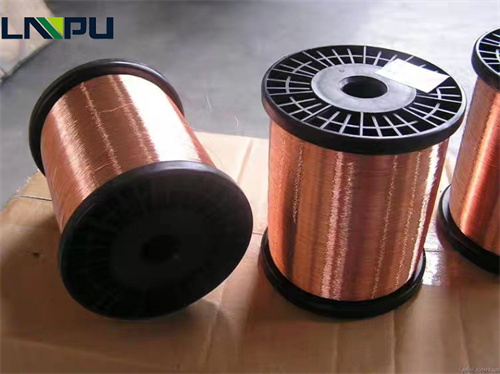

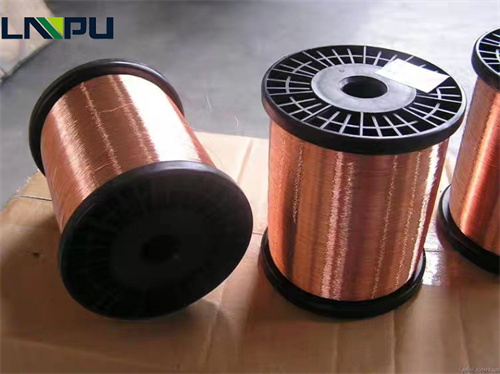

Winding wire copper enamelled round 1.5 mm class H 180°C

Thermal Class: class H 180°C

Standard: IEC, NEMA, JIS, GB

Diameter: 1.5mm

LP Industry

LP Industry could also provides the enameled aluminum wire for transformers, such as flat aluminum wire and round aluminum wire.

At the heart of high-efficiency motors, special transformers, and electrical equipment operating in extreme environments lies a seemingly ordinary yet crucial component—enameled wire.

Technical Specifications:"Copper": Indicates the conductor material. Copper possesses excellent conductivity and mechanical strength, making it the most commonly used and reliable conductor material for winding wires, ensuring efficient power transmission and low loss.

"1.500 mm": This is the conductor's nominal diameter, accurate to the micrometer level. It directly determines the wire's current-carrying capacity, DC resistance, and space utilization efficiency under finite slot fill factor, serving as a fundamental parameter for design calculations.

"Class H" and "180°C": These are core indicators of its heat resistance. According to the International Electrotechnical Commission (IEC) standard, Class H insulation materials allow a maximum long-term operating temperature of 180°C. This means that the wire can maintain stable insulation performance and achieve its designed lifespan at 180°C.

"Polyimide or equivalent coating": To achieve Class H heat resistance, the coating typically uses polyimide, polyamide-imide, or a composite coating. These materials possess excellent thermal stability, chemical inertness, and superior mechanical toughness, providing durable protection in high-temperature, high-frequency, or harsh chemical environments.

Core Advantages: Why Choose H-Class 180°C Enameled Wire?The selection of this specific specification of enameled wire is primarily based on its outstanding performance under demanding operating conditions:

Superior Heat Resistance and Reliability: Its 180°C temperature rating enables stable operation in high-temperature environments, significantly improving the overload capacity and lifespan of motors or electrical appliances, especially suitable for equipment with limited heat dissipation or high self-heating.

Excellent Electrical and Mechanical Properties: The high-quality H-class varnish film has extremely high dielectric strength, effectively preventing inter-turn short circuits. Simultaneously, its good adhesion and flexibility can withstand mechanical stress during winding, embedding, and binding processes, preventing insulation damage.

Good Environmental Adaptability: High-grade insulating varnishes typically possess excellent chemical corrosion resistance (such as resistance to refrigerants and lubricating oils) and moisture resistance, making them suitable for mining, metallurgy, chemical, and special drive applications.