This standard applies to enameled round copper wires with thermal classes 130, 155, 180, 200, 220, etc. The wires are used to make electromagnetic windings in electrical equipment such as motors, transformers, inductors, relays, etc.

ScopeThis part of IEC 60317 specifies the general requirements of enamelled round copper winding wires with or without bonding layer, of class 105, 120, 130, 155, 180, 200, 220 and 240, with different types of enamel covering.

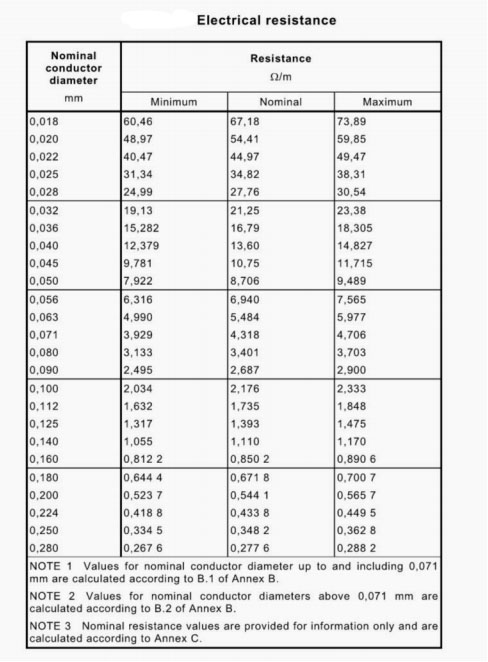

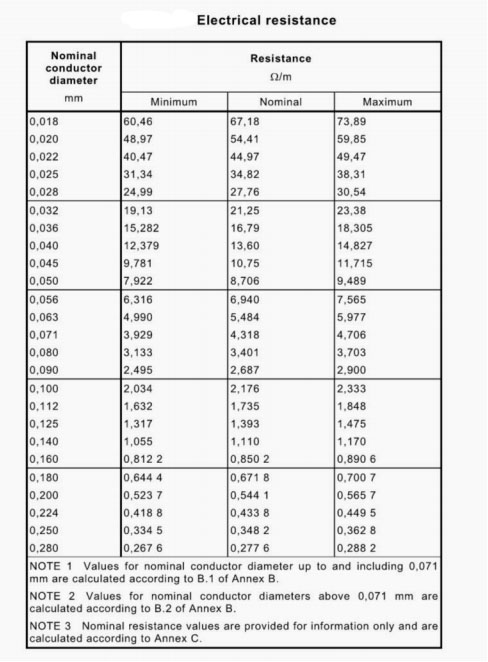

The range of nominal conductor diameters covered by this standard is:

Grade 1: 0.018 mm up to and including 2.500 mm

Grade 2: 0.020 mm up to and including 5.000 mm

Grade 3: 0.040 mm up to and including 5.000 mm

This standard also establishes the general requirements for enamelled round copper wires, such as mechanical, electrical, chemical, and thermal properties, and the test methods to be used for conformity assessment.

Dimensions and TolerancesThe actual diameter of the bare conductor (before enamelling) and the overall diameter of the enamelled wire (after enamelling) shall lie within the tolerances specified.

1. Conductor Diameter Tolerances

The tolerance on the nominal diameter of the bare copper conductor shall be as follows:

| Nominal Diameter (mm) |

Tolerance (± mm) |

| Up to 0.050 |

0.002 |

| > 0.050 to 0.100 |

0.003 |

| > 0.100 to 0.200 |

0.004 |

| > 0.200 to 0.315 |

0.005 |

| > 0.315 to 0.500 |

0.006 |

| > 0.500 to 0.800 |

0.008 |

| > 0.800 to 1.250 |

0.010 |

| > 1.250 to 2.000 |

0.013 |

| > 2.000 to 3.150 |

0.016 |

| > 3.150 to 5.000 |

0.020 |

2. Overall Diameter (Enamelled Wire) Tolerances

The overall diameter of the enamelled wire depends on the grade of enamel covering:

Grade 1: Thinner insulation

Grade 2: Medium insulation

Grade 3: Thicker insulation

The minimum and maximum overall diameters are specified in the standard for each nominal conductor diameter and grade.

AppearanceThe surface should be smooth and uniform;

No bubbles, cracks, peeling, mechanical damage, etc. are allowed;

No exposed bare copper is allowed.

Electrical PropertiesBreakdown voltage: The insulation layer should be able to withstand a certain voltage without being broken down;

Dielectric strength: The minimum breakdown voltage is specified according to different wire sizes and insulation levels.