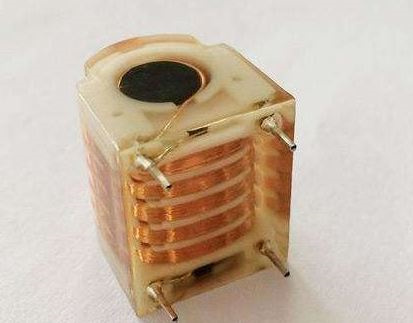

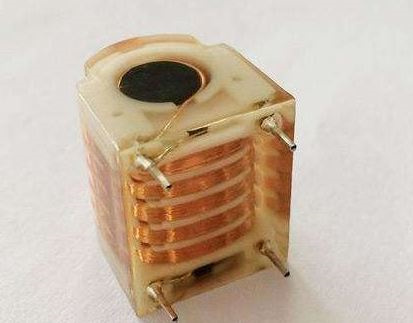

High-speed machine-wound special wire refers to special wire used for high-speed machine-wound wire equipment. These wires have specific physical and electrical properties that are suitable for the fast and accurate winding requirements of high-speed machine-wound wire.

The following are some characteristics and applications of high-speed machine-wound special wires:

High conductivity: High-speed machine-wound special wires usually use highly conductive materials, such as copper or aluminum. This material is able to provide low resistance and high conductivity to ensure the efficiency and performance of current transfer in the coil.

Insulation properties: High-speed machine-wound special wires usually have excellent insulation properties to prevent current leakage or short circuits in the coils. This insulating property helps improve the safety and reliability of electrical equipment.

Strength and flexibility: High-speed machine-wound special wires need to have sufficient strength and flexibility to adapt to the high-speed rotation and winding movements of high-speed machine-wound wire equipment. This ensures that the coil wire is not easily broken or deformed during the winding process.

Dimensions and specifications: The dimensions and specifications of high-speed machine-wound special wire are usually customized according to specific winding requirements and equipment requirements. These parameters may include wire diameter, number of coil layers, wire length, etc. to suit the specific coil design and winding task.

Temperature tolerance: Because electrical equipment may operate in high-temperature environments, high-speed machine-wound specialty wires generally have good temperature tolerance. They maintain the stability of electrical and insulation properties under high temperature conditions.

When it comes to high-speed machine-wound specialty wire, here is some further information:

Wire diameter selection: The wire diameter selection of high-speed machine winding special wire is determined according to the specific winding requirements and equipment requirements. Smaller wire diameters can be used to wind small coils, while larger wire diameters are suitable for larger coils. Wire diameter selection is also subject to current load and heat dissipation considerations.

Insulating materials: High-speed machine-wound special wires usually use high-performance insulating materials to ensure good insulation performance. Common insulation materials include polyurethane (Polyurethane), polyimide (Polyimide) and polyetherketone (Polyetherketone). These materials have excellent insulation properties and heat resistance.

Winding performance: Special wire for high-speed machine winding needs to have good winding performance to adapt to the requirements of high-speed machine winding wire equipment. They should have low friction coefficient and good bending properties to ensure smooth movement and high efficiency during coil winding.

Number of coil layers: The choice of high-speed machine winding special wire also depends on the number of coil layers. Coils with more layers usually require thinner, more flexible wire to make it easier to wind and assemble.

Strength and wear resistance: High-speed machine winding special wire needs to have sufficient strength and wear resistance to withstand the tension and friction during high-speed rotation and winding. This helps ensure wire integrity and winding quality.

Temperature resistance: High-speed machine-wound special wires usually require good temperature resistance to adapt to working conditions in high-temperature environments. They should be able to maintain the stability of electrical performance and insulation performance at high temperatures to ensure the reliability and safety of electrical equipment.

Quality control: Quality control is very important when using high-speed machine-wound special wires. Manufacturers should ensure that the wire meets relevant quality standards and specifications and conduct necessary quality inspections and tests to ensure the quality and performance of the coil.

Generally speaking, high-speed machine-wound special wire is a special wire designed according to the requirements of high-speed machine-wound wire equipment. They have specific physical and electrical properties to meet the fast, accurate and efficient requirements of high-speed winding processes. Choosing appropriate high-speed machine-wound special wire is crucial to ensure the quality, performance and reliability of the coil, and plays an important role in improving production efficiency and production quality.