Breakdown voltage tests typically follow international standards (such as IEC 60317, NEMA MW 1000, and GB/T 6109.2).

This is a destructive test that causes irreversible damage to the sample being tested, rendering the broken-down point unusable.

Impact: This means that every meter of product cannot be fully inspected; only sampling is possible. Therefore, in-line pinhole detection (non-destructive) during production is particularly important.

What is breakdown voltage?The maximum voltage that can be withstood when an AC voltage is applied continuously from zero between two cross-coated enamel wire specimens until the paint film is destroyed (i.e., electrical breakdown occurs, short-circuiting the two conductors). The unit is usually volts (V).

Why is breakdown voltage so important?

Why is breakdown voltage so important?After enamel wire is wound into a coil, a potential difference (voltage) exists between turns, between layers, and between the coil and the core. Especially during equipment startup, sudden load changes, or lightning surges, transient overvoltages far exceeding those experienced during normal operation can be generated.

Preventing interturn short circuits: If the breakdown voltage of the paint film is lower than the operating or transient voltage, it will break down, causing a short circuit in adjacent conductors (interturn short circuit). This short circuit can cause localized overheating, burn out the coil, and ultimately render the entire motor or transformer useless.

Ensuring equipment reliability and lifespan: A high and stable breakdown voltage is the cornerstone of long-term, safe operation of electrical equipment. It ensures that the insulation system can withstand various electrical stresses.

Adapting to high-frequency and high-voltage applications: In modern applications such as new energy vehicle drive motors, photovoltaic inverters, and variable-frequency air conditioners, the operating frequencies and voltages are higher, placing even more stringent requirements on the breakdown voltage of enameled wire.

Key Factors Affecting Breakdown Voltage:The breakdown voltage isn't determined by a single factor; it's closely linked to the entire manufacturing and use chain of enameled wire.

| Factor |

Description |

| Paint Film Thickness |

Thicker paint films generally increase the breakdown voltage. However, excessively thick films can reduce heat dissipation and flexibility, so a balance is necessary. |

| Paint Type (Material) |

Different types of insulating paint have inherently different dielectric strengths. For example, polyimide (PI) has a much higher dielectric strength than polyester (PE). |

| Painting Process |

Uneven paint application, impurities, and insufficient (or over-curing) paint can create weak points, significantly reducing the breakdown voltage. |

| Conductor Surface Quality |

Burrs, pits, oxidation, or stains on the surface of copper conductors can distort the electric field, acting like pinpoints, easily causing partial discharge and breakdown. |

| Pinhole Defects |

Extremely tiny holes (invisible to the naked eye) in the paint film are the Achilles' heel of insulation, allowing voltage to easily penetrate through these holes. |

Why is breakdown voltage testing necessary for enameled wire?

Breakdown voltage testing provides a direct reflection of enameled wire quality. Raw material issues: Burrs and pits on the copper rod surface, or substandard insulating paint, can directly lead to a decrease in breakdown voltage.

Painting process issues: Poor paint molds and improper baking temperatures can result in uneven paint films, bubbles, inadequate curing, or pinholes. These defects manifest themselves as low breakdown voltage values or significant data variability during testing.

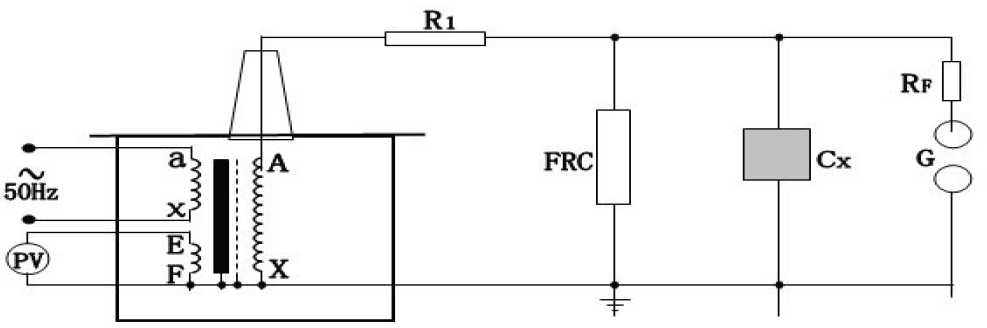

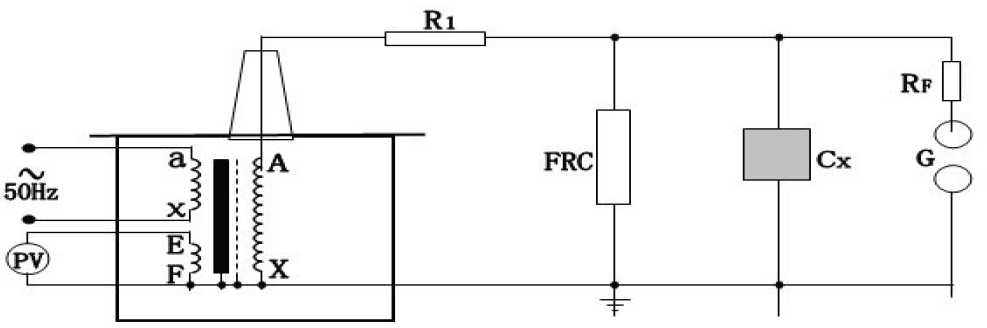

Online monitoring: While breakdown voltage testing itself is a sample-based destructive test, the online pinhole detector (a non-destructive, low-voltage test) commonly used on production lines shares the same principle and can 100% detect and flag products with pinhole defects.

Breakdown voltage is the "gatekeeper" of the insulation life of enameled wire