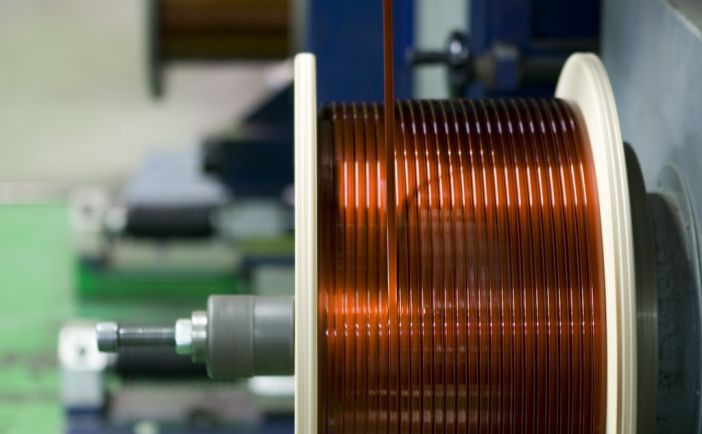

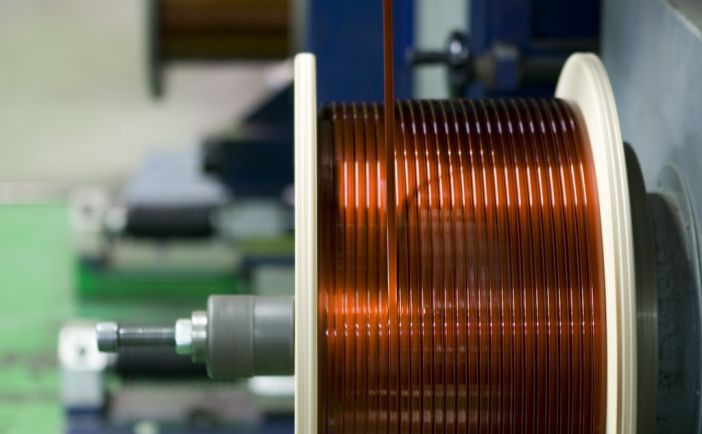

In the realm of electrical engineering, wires play a pivotal role in transmitting power and information. Among the myriad options available, the 1.50mm Grade 2 Class F Enamelled Copper Polyurethane Winding Wire stands out as a true powerhouse. This wire is a staple in numerous applications, thanks to its remarkable properties and versatility. In this blog post, we will delve into the intricacies of this wire, exploring its composition, applications, and advantages.

The Composition: A Blend of Excellence

The Composition: A Blend of ExcellenceCopper Core:

At the heart of this wire lies a core made of high-grade copper. Copper is chosen for its excellent electrical conductivity, making it an ideal material for transmitting electrical signals and power. Grade 2 copper, in particular, is known for its high purity and durability, ensuring optimal performance over time.

Enamel Coating:

Wrapped around the copper core is a layer of enamel insulation. Enamel, a type of polymer, provides electrical insulation and protection to the wire. This insulation is crucial for preventing short circuits and ensuring the wire can operate reliably even in demanding conditions.

Polyurethane (PU) Coating:

The outermost layer is made of polyurethane, a synthetic polymer known for its exceptional mechanical properties. This coating adds an extra layer of insulation and also provides protection against abrasion, chemicals, and moisture.

Applications: Where Power Meets Precision

The 1.50mm Grade 2 Class F

Enamelled Copper Winding Wire finds its applications in a wide array of industries, owing to its exceptional characteristics.

Transformers:

This wire is a key component in transformers, where it facilitates the efficient transfer of electrical energy between the primary and secondary coils.

Electric Motors:

In electric motors, this wire is used for winding the coils, ensuring optimal electromagnetic performance.

Inductors and Solenoids:

Inductors and solenoids, commonly found in electronics, benefit from the reliable and efficient performance of this wire.

Electromagnetic Devices:

Various electromagnetic devices, such as relays and actuators, rely on this wire to function effectively.

Automotive Industry:

From ignition systems to sensors, this wire plays a vital role in the automotive sector, ensuring smooth operation and reliability.

Advantages: The Edge of Excellence

High Electrical Conductivity:

The use of high-grade copper ensures minimal electrical resistance, allowing for efficient power transmission.

Excellent Insulation Properties:

The enamel and polyurethane coatings provide robust electrical insulation, safeguarding against short circuits and ensuring reliable performance.

Mechanical Resilience:

The polyurethane coating adds a layer of protection, making the wire resistant to abrasion, chemicals, and moisture, enhancing its longevity.

Wide Temperature Range:

With a Class F insulation rating, this wire can operate at temperatures up to 155°C, making it suitable for high-temperature environments.

Versatility:

Its adaptability across various industries and applications showcases its versatility and reliability.

Conclusion: Empowering the World of Electrical Engineering

The 1.50mm Grade 2 Class F Enamelled Copper Polyurethane Winding Wire stands as a testament to the innovation and precision that underpins modern electrical engineering. Its exceptional composition, coupled with a wide range of applications and unparalleled advantages, makes it an indispensable component in a myriad of electrical devices and systems.

From transformers to electric motors, this wire is the unsung hero that enables our modern world to function with efficiency and reliability. Its legacy continues to grow as it finds new applications in emerging technologies, solidifying its place as a cornerstone of electrical engineering.